Sensor types Įarly technologies included mercury thermometers with electrodes inserted directly through the glass, so that when a certain (fixed) temperature was reached the contacts would be closed by the mercury. Electronic thermostats have an electronic equivalent. When correctly adjusted this reduces any excessive hysteresis in the system and reduces the magnitude of temperature variations. To improve the comfort of the occupants of heated or air-conditioned spaces, bimetal sensor thermostats can include an "anticipator" system to slightly warm the temperature sensor while the heating equipment is operating, or to slightly warm the sensor when the cooling system is not operating. This reduces the risk of equipment wear from too frequent switching, although it introduces a target system temperature oscillation of a certain magnitude. For example, a refrigerator set to 2 ☌ might not start the cooling compressor until its food compartment's temperature reaches 3 ☌, and will keep it running until the temperature has been lowered to 1 ☌. Instead of changing from "on" to "off" and vice versa instantly at the set temperature, a thermostat with hysteresis will not switch until the temperature has changed a little past the set temperature point. To prevent excessively rapid cycling of the equipment when the temperature is near the setpoint, a thermostat can include some hysteresis. The rate at which the target system temperature can change is determined both by the capacity of the heating or cooling equipment to respectively add or remove heat to or from a target system and the capacity of the target system to store heat. Increasing the difference between the thermostat setting and the desired temperature therefore does not change the time to achieve the desired temperature.

Thermostatic damper draft control full#

Instead, the heating or cooling equipment runs at full capacity until the set temperature is reached, then shuts off. A thermostat is an example of a " bang-bang controller" as the heating or cooling equipment output is not proportional to the difference between actual temperature and the temperature setpoint. Electronic thermostats, instead, use a thermistor or other semiconductor sensor that requires amplification and processing to control the heating or cooling equipment. In one form, the mechanical thermostat, a bimetallic strip in the form of a coil directly operates electrical contacts that control the heating or cooling source. Thermostats use different types of sensors to measure the temperature. Examples include building heating, central heating, and air conditioners, kitchen equipment such as ovens and refrigerators, and medical and scientific incubators. Thermostats are used in any device or system that heats or cools to a setpoint temperature. A thermostat can often be the main control unit for a heating or cooling system, in applications ranging from ambient air control to automotive coolant control.

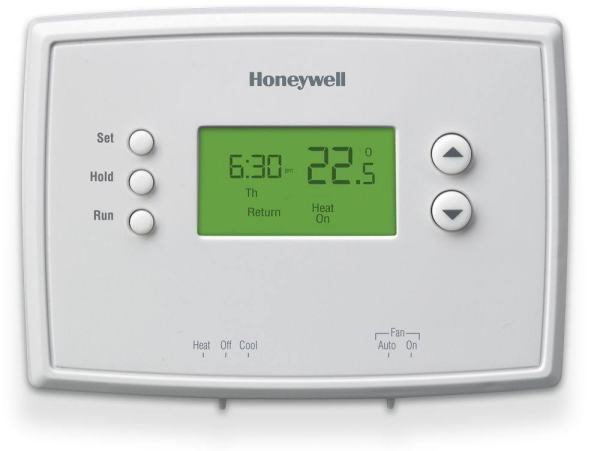

Ī thermostat operates as a "closed loop" control device, as it seeks to reduce the error between the desired and measured temperatures. Thermostatically controlled loads comprise roughly 50% of the overall electricity demand in the United States. In scientific literature, these devices are often broadly classified as thermostatically controlled loads (TCLs). Thermostats are used in any device or system that heats or cools to a setpoint temperature, examples include building heating, central heating, air conditioners, HVAC systems, water heaters, as well as kitchen equipment including ovens and refrigerators and medical and scientific incubators. A Honeywell electronic thermostat in a retail storeĪ thermostat is a regulating device component which senses the temperature of a physical system and performs actions so that the system's temperature is maintained near a desired setpoint.

0 kommentar(er)

0 kommentar(er)